Acidic Mecer process

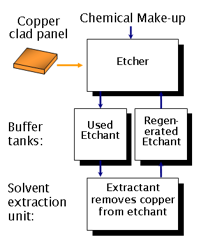

The First stage

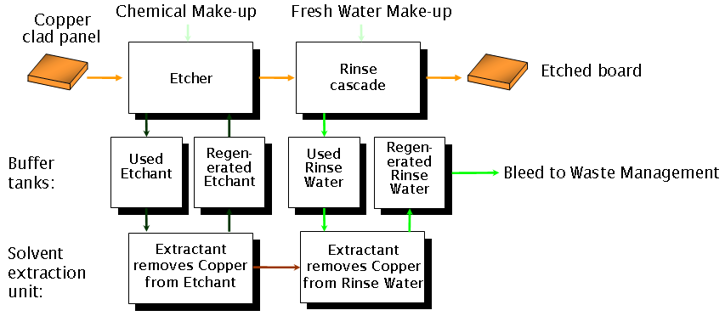

The Second stage

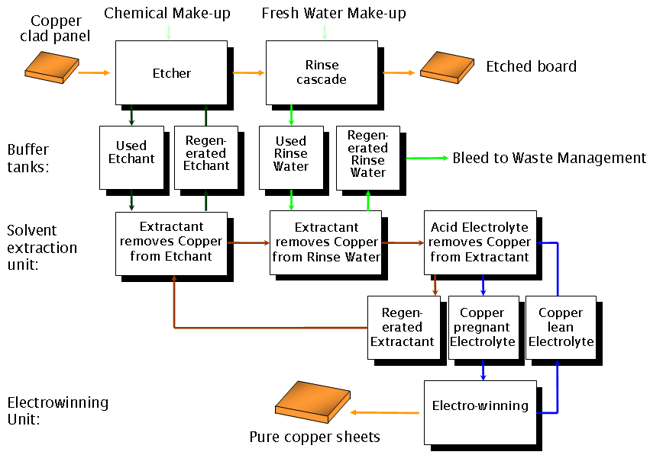

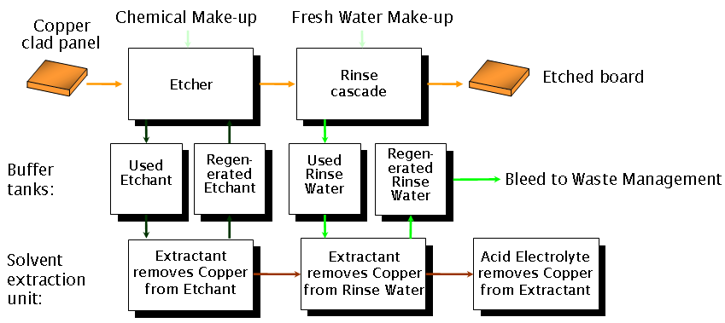

Used rinse water is passed through the third stage of extraction whereby the copper concentration drops from approx. 8 g/l to < 0.1 g/l. In order to accomplish this some caustic soda is fed to the extraction stage.

The Third stage

Acid electrolyte from the electrowinning cell is passed through the fourth and fifth stages for reextraction increasing its copper concentration before being returned for continuous copper plating in the electrowinning cell.

Electrowinning unit

The copper loaded acid (electrolyte) travels from the forth and fifth extraction stages to the electrowinning cell where the copper is plated onto copper starter sheets. When a cathode's weight reaches ~125 kg it is removed from the system and sold as electrolytic grade copper.

The process of plating the copper regenerates the acid in the electrolyte so that it is ready to be used again to strip the copper from the organic.